PIEZO ELEMENT SPECIFICATION

Customer: | Part No: | |||||

Product: Piezoelectric elements | DT Part No: FT15W30-8.0(切边) | |||||

一、Configuration | ||||||

Appearance and dimension: see the drawing | ||||||

Material | Piezo electric | |||||

Configuration | 1:plane√ 2:discal | |||||

Electrode form | A: fullness √ B: feedback | |||||

Metal material | T: brass√ G: stainless steel F: fe | |||||

二,Electrical specification | ||||||

Resonant frequency (kHz) | FS=8.0±0.5 | |||||

Resonant impedance (Ω) | Rr≤500Ω | |||||

Capacitance at 120Hz (PF) | Cm=10000±30% | |||||

Operating temperature (℃) | -30~+60 | |||||

Storage temperature (℃) | -30~+70 | |||||

Piezoelectric elements Manual Soldering process | Soldering Parameter | |||||

Temp.( 0C) | Time(Sec.) | Times | ||||

Inclusive Lead | silver electrode | 280±10 | 1.5 second or less. | 1~2 | ||

metal plate | 320±10 | 2 second or less. | 1~2 | |||

Lead Free | ★ | silver electrode | 310±10 | 2 second or less. | 1~2 | |

★ | metal plate | 330±10 | 3 second or less. | 1~2 | ||

Solder Dot: Diameter MAX 3.0mm, High MAX 1.5mm, Soldering sequence: 1、 silver electrode 2、 metal plate | ||||||

Remark: ★ DT Instance Soldering Process

APPEARANCE UNIT:mm

.png)

![]()

备注:线材UL1571AWG32#

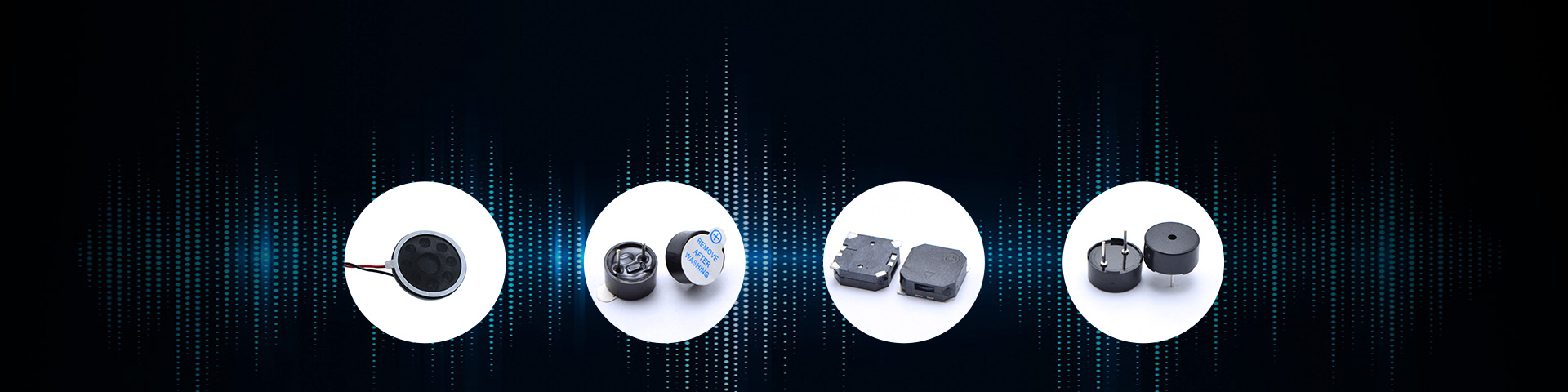

MORE SPECIFICATIONS FOR

PIEZOELECTRO TRANSDUCER

1、Oscillating system

Basically, sound source of a piezoelectric sound component is a piezoelectric diaphragm consists of a piezoelectric ceramic plate which have electrodes on both sides and a metal plate (brass or stainless steel etc.).

When alternating voltage is applied to piezoceramic element, the element expands or shrinks diametrically. This characteristic is utilized to make vibration plate bend to generate sounds.

.png)

.png)

2、Soldering procedures

A lead wire is needed to apply voltage to the piezoelectric diaphragm. When using a soldering iron, the optimum temperature for soldering a lead wire to a metal plate is 280±100C for 3 seconds and the same temperature for the ceramic silver electrode for 1~1.5 second or less. The lead wire should be as fine as possible, as it works as a load restricting oscillation of the piezoelectric diaphragm.

Hight 1.5mm MAX

a. Test condition: Solder Dot

Diameter 2.5m-3.0mm MAX

b. .png) Characteristics

Characteristics

1、 Perpendicular pull

Thickness Of Ceramic | Weight (g) |

0.10mm | 400 |

0.15---0.25mm | 700 |

.png) 2、Horizontal pull

2、Horizontal pull

Thickness Of Ceramic | Weight (g) |

0.10mm | 700 |

0.15---0.25mm | 2000 |

Lead wire

3、characteristics and measuring method

Characteristics

TYPE | Resonant frequency | Resonant impedance | Capacitance | Insulation resonance |

Piezoceramic element | ● | ● | ● | ● |

b. Measuring Procedure

When the piezoelectric diaphragm oscillates freely in air, the node does not move as show in fig.5 and fig.6.With this point held with a measuring terminal, the resonant frequency and resonant impedance are measured in the constant-current circuit.

.png)

.png)

4、Reliability Test

ITEM | TEST CONDITION AND REQUIREMENT | |

4.1 | High Temperature Test 高温测试 | 将蜂鸣片置于 70±2℃ 中,试验保温时间不少于30min,在高温下测试。 允许谐振频率的变化值: ±15%, 自由电容的变化值: ±30%. |

4.2 | Low Temperature Test 低温测试 | 将蜂鸣片置于 -10±2℃ 中,试验保温时间不少于30min,在低温下测试。 允许谐振频率的变化值: ±15%, 自由电容的变化值: ±30%. |

4.3 | Test Temperature Cycle Test 温度循环测试 | 蜂鸣片在-10℃暴露30min, 在70℃暴露30min,五次循环后,试验后在常温下恢复1h,电性能变化符合以下: 谐振频率的变化值: ±10%, 自由电容的变化值: ±20% |

4.4 | Humidity 湿热 | 蜂鸣片置于温度在+32℃,相对湿度在90%-5%~90%+5%中,保持96h后,试验后在常温下恢复2h测试,电性能变化符合以下: 谐振频率的变化值: ±10%, 自由电容的变化值: ±20% |

4.5 | Drop Test 跌落 | 将蜂鸣片放置在水平位置,金属片的一面朝下,从1000mm高度自由跌落到硬木版上,跌落两次后,检查外观并测量电性能。 蜂鸣片应符合规格书要求。 |

4.6 | Vibration Test 振动 | 将蜂鸣片置于10~55Hz、振幅在0.35mm、扫频循环5次振动等级中,在两个互相垂直的轴线方向上振动试验后,应无机械损伤,电性能变化符合规格书要求。 |

4.7 | Silver Solderability Test 银层焊接强度 | 用20W内热式电烙铁,HISnPb39焊锡丝,松香酒精焊剂,焊接时间小于5s,焊接面积3m㎡~5m㎡,焊接点堆积高度小于2mm,在蜂鸣片银层面上,按垂直和水平方向焊接两根与蜂鸣片成90°±5°和180°±5°的导线,在导线上施加以下负荷,负荷时间为10s±1s。 通常在蜂鸣片银层上焊接Φ0.15×7多股导线,垂直方向能够承受2.5N拉力,水平方向能承受25N拉力,银层无机械损伤为合格。 |

4.8 | Adhesive strength 粘结强度 | 用直径与压电陶瓷片相同的圆柱体金属棒,长度为60mm左右,把蜂鸣片的金属面贴在金属棒的曲面上,将其压至与曲面相吻合后,检查外观。蜂鸣片经折弯一次后,应无瓷片脱落和翘起现象,但允许龟裂。 |

.png)